NPE Booth W2761

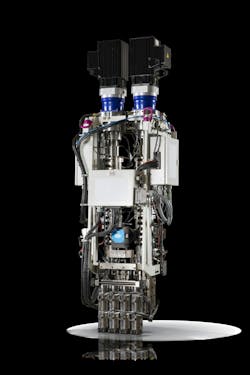

Blow molding machines Available in many sizes and models, Bekum’s extrusion blow molding machines can produce both small and large packaging, canisters, intermediate bulk containers, drums, water tanks and a wide range of technical parts, including air ducts.

What’s new? Tri-extrusion units that can be retrofitted to existing blow molders.

Benefits The ability to provide Bekum blow molding machines with multi-layer capabilities. The tri-extrusion units provide uniform melt and layers, producing high-quality parts that incorporate a middle layer of PCR, typically at around 60 percent of part weight. The tri-extrusion units allow for virgin material savings, greater efficiency and are easily added to existing machines. With the units, users can maximize productivity, speeding up production and lowering energy consumption. The tri-extrusion units are compatible with Bekum’s smaller machines, up to the H-155 and EBlow 407D.

Bekum America Corp., Williamston, Mich., 517-655-4331, www.bekumamerica.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.

David Tillett

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.