NPE Booth W1167

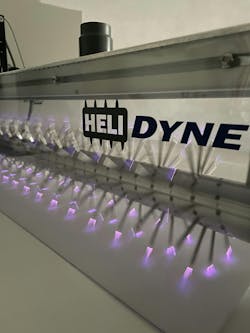

HeliDyne This patented system from 3DT, which manufactures plasma and corona treatment systems, features numerous pin electrodes. This array of electrodes allows the machine to produce a wide band of corona discharge, raising surface tension and functionality on many difficult-to-treat materials. HeliDyne has as PLC-based control system with a touch-screen HMI, and the machine’s frequency-matching feature allows for optimum treatment levels and efficient production.

What’s new? HeliDyne, which features a new type of helix electrode arrangement.

Benefits The ability to treat wide, thick, porous, hollow and oversized materials. While most corona treaters can treat rolls of thin film or small areas of 3D parts, HeliDyne also can treat such materials as foam stock, honeycomb boards and polymer panels nearly 7 feet wide and 1 inch thick. While conventional surface treatment can cause heat damage to these materials, HeliDyne provides gentle corona treatment. It is equally effective for cut-to-size sheets and in-line applications. Customers can choose between single- or double-sided treatment, and the HeliDyne system is fully customizable.

3DT LLC, Germantown, Wis., 262-253-6700, www.3DTLLC.com

About the Author

David Tillett

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.