Bulk-purchasing habits, demand for sustainability drive packaging changes

By Karen Hanna

At Altium Packaging, efforts to go green and save brand owners’ money have culminated in numerous packaging advances that could show where the market is headed. The company, which designs packages, as well as molds products such as vials and caps, is at the center of change, trying to make packages that perform well — while leaving a light footprint.

Priorities can often collide.

“How do you solve a perfect storm of challenges? You want to be aesthetically pleasing, but it has to ship through e-com[merce], and you don’t want it to stress-crack … so, you put all that together, to have the technical resources to help, in design and engineering, to be able to commercialize it,” said John Manderfield, VP of creative design for Altium.

Toughening up containers so they can be reused is just one tack companies are taking as they explore ways to reduce their environmental impact.

Cleaner living with alternatives to virgin resin

In recent years, many brand owners have set aggressive timetables for increasing their use of post-consumer resin (PCR). Others, such as Costco, are embracing new materials, including bio-resins.

The wholesaler sells its store-brand Kirkland Signature Ultra Clean HE plant-based liquid laundry detergent in a bottle made from bio-resins, designed by Altium. The detergent bears the EPA/Safer Choice logo, which signifies that the product’s formula contains ingredients with greener characteristics than conventional products of the same type.

Joe Palmer, technical fellow for Altium, said while most emerging materials can be processed using conventional equipment, the promises that PCR and bio-resins offer are a long way from fruition.

When it comes to packaging components, such as pouring necks and handles, PCR isn’t as sturdy as virgin resin; it also fails to deliver the same shelf appeal, with the colors and finish of products appearing off-spec.

“So, for example ... the Seventh Generation detergent, we hit a ceiling or a limit on how much recycled content we can include; now here we’re talking about 70 or 80 percent, but still, the customer would like to have that at 100 percent. But, in some cases, you can’t quite cross that line because of the geometry of the package or other constraints on requirements,” he said. “In other cases, we can get there.”

Performance is just one challenge.

“I think there’s a lot of pressure on that,” Palmer said. “That will take some effort to make that function, not just on the design side, but also on the supply side of the material. On a bio-based or plant-based side, I think the challenge there is in the raw-material supply and on scale and cost. And, although it’s certainly proven viable at some scale, it’s certainly not enough to supply our packaging market or even a significant portion of it yet here in North America. [Whether] the economics are going to make sense versus predominantly petrol-based, I don’t know if anyone knows that answer, but I think this will take longer than PCR.”

Finding strength with less weight

Driven by both cost and environmental pressures, lightweighting is a popular strategy that, in many cases, might be reaching its limits.

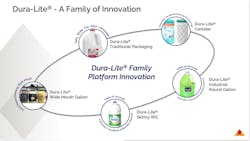

“One aspect of sustainability would be taking plastic out of the package, reducing the virgin plastic that it’s composed of,” said Manderfield, who pointed to Altium’s Dura-Lite line of bottles as an example of a lightweighting success story.

Designed to minimize the use of resin, Dura-Lite bottles are available in a variety of styles appropriate for a range of liquids, including oils, automotive fluids, chemicals and beverages.

One popular bottle in the line is the Dura-Lite milk jug, which uses just 56 grams of resin, compared with 62 grams in comparable milk bottles that use conventional designs.

“That’s a significant achievement to take that much weight out. Multiply that by so many bottles, I think we’re up to the last stat I just saw … it’s 20 million pounds of virgin plastic saved on that particular package,” Manderfield said.

But lightweighting can only go so far, Palmer said.

“I think there are some hopes for advanced materials that might allow 50 percent lightweighting from where we are now, but those are really more far out, more developmental. I think anything we’re talking about in terms of lightweight is usually on the order of 20 percent or less from where we are right now. There are plenty of exceptions, but, typically, people have already looked at the problem and got the package as light as they can,” he said. “... It’s not like we’re changing this by orders of magnitude.”

Balancing competing needs

Brand owners’ packaging strategies differ. So do their goals, which aren’t always compatible.

On one hand, brand owners and consumers are looking for greater sustainability; on the other hand, circumstances might also demand packages that are tougher, heavier or more robust.

For example, Palmer pointed to the rise in popularity of e-commerce and bulk buying — two shopping experiences that call for packaging that’s a bit different than what’s on the shelf at more traditional brick-and-mortar retailers.

But with even traditional retailers having trouble attracting and retaining workers, there’s more appeal than ever for packaging that can be stacked and displayed atop the same pallets on which it’s shipped.

“If you go to big-box stores, those guys probably want to keep their store labor down, so, they’re going to want to drop a pallet off, to have the consumer pull [the product] off, rather than have someone stocking shelves,” Palmer said. “That causes consumers now to interact with the pallets.”

That change demands packaging that’s strong enough to be stacked.

Just as calls to reduce or eliminate packaging altogether are growing, so, too, is the need for stronger packaging.

“Certainly, looking at design for durability and impact in the e-commerce channel, going through the mail or through individual delivery, it requires some design to address the packaging toughness. But, then, also, in the case of bottles, we have to be more attentive to leak prevention, because those bottles are shipped and moved around in any orientation, not just upright,” Palmer said.

Finding a good fit between balance, performance and appearance isn’t always easy.

“Not always a solvable problem,” he conceded.

Compromise could be in order.

“If you want to have a returnable package, you need something that’s mechanically strong, right? That is often easier to accomplish with more mass, right? It’s not [a matter of] lightweighting, but heavy-weighting to be able to get something that’s returnable,” he said. “Ideally you can do both, but you can’t. But there are achievable balances between those two things.”

Karen Hanna, associate editor

Contact:

Altium Packaging, Atlanta, 678-742-4654, www.altiumpkg.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.