CAM software makes processing part data for CNC machines easy

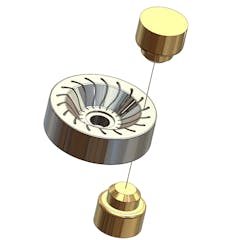

CAMWorks This intuitive, feature-based CAM software can help mold makers to automate and maximize CNC machining efficiency. Once parts are designed in CAD software, the CAD file is imported into CAMWorks, which defines the machining operations needed to cut the part on the machine, as well as the tools that will be used, the feed/speed rates of the cutting, the toolpaths and other factors. This data is then converted to G-code — the programming language used by cutting machines that are used to make molds and tooling. CAMWorks, from HCL Technologies Ltd., Noida, India is available worldwide through a large network of resellers. USA Geometric Americas is an HCL company.

What’s new? A new module for wire electrical discharge machining (EDM). Compatible with the most advanced EDM machines, it includes enhanced feature recognition for non-planar geometry.

Benefits One-click transformation from design model to G-code, saving users significant amounts of time. The program automatically pulls data from the CAD model, so users don’t have to extract this data manually from the CAD model. It automatically searches the part for machinable features, identifies the features and generates all the operations with the users’ preferences and settings, and creates toolpaths. It allows even complex two-axis parts, two-axis parts with tapers and four-axis wire EDM parts to be programmed in a single click. In addition to its other advantages, CAMWorks is fully integrated with SolidWorks, so CNC users don’t need to extract any lost data from the model or re-create any contours or dimensions to generate G-code.

USA Geometric Americas Inc., Scottsdale, Ariz., 480-367-0132, https://camworks.com