Coperion feeder handles hard-to-recycle material

By Karen Hanna

An updated feeder from Coperion can handle waste plastic once considered not worth recycling, with throughputs exponentially higher than other technologies. The company is also releasing an update to a pelletizer line at the K Show.

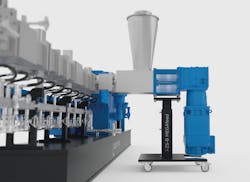

At the show, the newest version of Coperion’s ZS-B side feeder, the ZS-B Megafeed, will feed plastic waste with a bulk density of less than 12.5 pounds per cubic foot into a ZSK twin-screw extruder, which will recycle and compound the material.

The feeder can process a wide variety of materials at high rates — including PA, PE, PET and PP — in fiber and flake form. It can handle low-bulk-density material without agglomeration, a step required in other recycling processes that consumes significant time and energy.

It feeds flakes and fibers directly into the ZSK extruder, where they are recycled.

“Very high throughputs in both mechanical and chemical recycling of post-industrial and post-consumer waste are achieved,” the company states in a press release.

According to Coperion, conventional feeders handling PA fibers with a bulk density of around 3 pounds per cubic foot could process about 154 pounds per hour; in contrast, the ZS-B Megafeed feeder and ZSK extruder can handle about 2,200 pounds per hour. The improvement is similarly stark with carbon fibers — a material that typical feeders can move at rates of about 110 pounds per hour, with the ZS-B Megafeed system capable of around 5,500 pounds an hour.

Throughputs increased from 100 pounds per hour to more than 1,400 pounds per hour when recycling PCR flakes, and from about 176 pounds per hour to more than 2,800 pounds per hour with multilayer film flakes.

Overall, the Coperion feeder achieves throughput increases about 14 times higher than typical feeders, according to numbers provided by the company.

In addition, Coperion’s recycling portfolio at the K Show will include its SP series of dual bearing strand pelletizers, which have been updated to reduce downtimes and improve pellet quality. The pelletizers produce a consistently high cut quality, even when handling soft polymers.

Three sizes — the SP140, SP240 and SP340 — are available, with hourly throughputs ranging from 220 pounds to about 6,600 pounds.

The pelletizers feature an optimized intake area that continuously guides pellet strands into a newly designed, more-compact cutting chamber. The cutting rotor’s flanges have been optimized to use the entire width of the rotor. With very little dead space, the optimized cutting area is easier to clean.

According to the company, operators can adjust the cutting gap easily with no tools, and setup of the system takes significantly less time than previous versions required.

K Show visitors can learn more about Coperion’s innovations at Hall 14, Booth B19.

Contact:

Coperion, Dhruv Lad, sales director North America, dhruv.lad@coperion.com, www.coperion.com

Karen Hanna, senior staff reporter

Karen Hanna | Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.

Request More Information