Progressive's line of ejector pins nixes need for step grinding

NPE Booth W1543

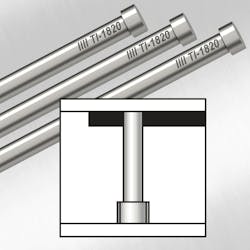

TI ejector pins These Progressive Components pins have applications for mold makers who might otherwise use stamping punches as core pins in molds. The pins — the TI stands for thousandths increment — are manufactured with hardened M-2 steel. With heads precision ground to mold tolerances, they are available with diameters from 0.06 inch to 0.32 inch in a standard length of 2.5 inches.

What’s new? The addition of a new length of 5.5 inches, which brings to 534 the number of pins in the line.

Benefits Elimination of step grinding, which is sometimes needed for a final fit. TI pins need only be cut to the finished length to be ready for use with mold inserts that have been wire-EDM’d to the molded part diameter. Progressive’s TI pins are designed to fit into small, crowded cavities and core inserts, and cut-to-length and custom options are available.

Progressive Components, Wauconda, Ill., 847-487-1000, www.procomps.com

David Tillett | Associate Editor

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.