NPE Booth W361A

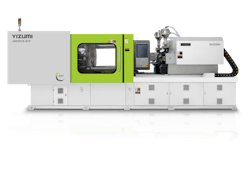

CE-P This platform of tie-bar-free all-electric presses, part of Yizumi’s C series, offers clamping forces ranging from 165 tons to about 600 tons. According to the company, the C in the name of the series stands for color, and the series includes machines for multi-component molding. The other letters in the CE-BTP platform are: E for servo-electric, B for broad platen, T for turntable and P for the machines’ parallel injection units.

What’s new? The all-electric platform of machines, making its U.S. debut at NPE with a demonstration of the 258-ton UN230CE-BTP. At the show, it will produce a two-color, 2.8-ounce liquid-silicone-rubber (LSR) collapsible lunch box in 85-second cycles.

Benefits Energy-efficiency, molding accuracy, and repeatability of clamping force and mold opening and closing, long mold life and the production of high-quality products. The CE-P machines’ high degree of platen parallelism ensures they can meet the needs of LSR molding. Their turntable technology allows for speed, accurate positioning and user-friendly operation. Also, Yizumi’s BFC — or balanced-force clamping — technology can adjust the clamping force transmission direction so that force is applied to the mold more evenly and molding is more precise and stable.

Yizumi-HPM Corp., Iberia, Ohio, 740-382-5600, www.yizumi-hpm.com

Vital Statistics

|

Injection molding machine at NPE |

UN230CE-BTP |

|

Machine dimensions |

About 20.3 feet by 7 feet by 8 feet |

|

Opening stroke |

21 inches |

|

Ejector stroke |

5.9 inches |

|

Possible mold thickness |

8.7 inches to 23.7 inches |

|

Space between tie bars |

3.1 feet by 1.9 feet |

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.