High resin prices, and at times material scarcity, have driven demand for the fillers and foaming agents iD Additives sells. And the capabilities of foaming agents have expanded — meaning customers sometimes still are surprised by the applications they’re suited to perform.

For iD Additives founder and President Nick Sotos, it all boils down to an obvious value proposition:

“We’re able to save people money when propylene is 40 cents, so when it’s 90 or 80 or 70, even though it’s coming down now, we still get phone calls, because we all know it’s going to go back up. And if we can save you money when it’s 40, why wouldn’t you look at it, and when it goes up, you’ll save more?”

No matter their material or geometry, most parts can be foamed or filled — or both — with advantages beyond just saving resin, Sotos and Technical Manager Ron Bishop said.

“Typically, when we’re talking with people, we tell them, ‘Look, our goal is [to save] 10 percent weight, 10 percent cycle,’ ” Sotos said.

The company has helped customers that make a wide range of products, including caps, closures, construction and agricultural items, shipping containers, gaylords, pallets, housewares and blown film. Thanks to advances in foaming, Bishop and Sotos have even helped on projects involving products with walls as thin as 0.011 inch — a development that Sotos said wasn’t possible just 10 years ago.

In some cases, the men said they’ve seen part weights go down 30 percent. For processors that want to cut costs or that have had trouble sourcing materials, the benefit is obvious.

“I think Nylon 6/6 for a while was in short supply,” Sotos said. “So, if you're running that … you're using this as an extender. … If you have 100,000 pounds of it, and you can save 10 percent on your parts, in reality, you can make 110,000 pounds worth of parts.”

But part weight is just part of the story.

Foaming agents reduce viscosity, allowing machines to process materials at lower temperatures and pressures, which saves energy costs and reduces cycle times, Bishop said. On the other hand, fillers, such as talc and calcium carbonate don’t offer the temperature benefit, but they add stiffness to parts and, like foaming agents, can reduce cycle times.

In separate trials involving an all-electric Sumitomo (SHI) Demag machine, the energy costs of injection molding with foaming agents were 10 and 18 percent lower, Bishop said.

Processors often can tap into the benefits of filler and foaming agents by using them together, Bishop said in a Zoom chat available on the company’s YouTube channel.

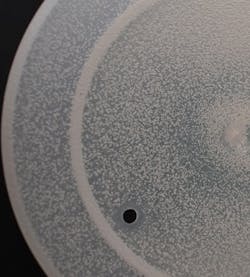

“I think the combination between a calcium and a chemical foam, they work really, really well together,” he said. “... The combination of the two, the great nucleating factor of the foam, makes the cell structures much smaller, and, when you add that 10 percent [filler], now your weights go up, but, if you add foam with it, you can actually pull the weights back down and you still get a stiffer ... more rigid part, and the cell structure is amazing.”

Exactly how much resin can be removed depends on part requirements, Bishop and Sotos said. While foaming won’t compromise aesthetics, fillers might — and both options have implications for part strength.

“When we deal with high-impact parts, or parts that require an impact, typically they have a range of impact. And mostly, if nobody’s using any foam or fillers in a particular part, they’re usually on the high end of that scale. But what we do is we bring the weights down and keep them within the spec of their impacts,” Bishop said.

In some cases, fillers can actually improve part characteristics, Sotos said.

As an example, he cited an application involving the base of a broom. Using fillers, the manufacturer was able to more effectively fill the part, so that it wouldn’t have voids in the areas where the bristles would be attached.

Fillers and foaming agents also have implications on the end of a part’s life. Filled parts can be ground up with other filled parts and recycled with them, while foamed parts can be recycled without issues, as the gases used in foaming are released in the recycling process.

In fact, Bishop said, recycled material is especially easy to foam.

“If I’m running 100 percent regrind, it foams extremely well, and I think mainly because it’s seen a history of heat, and so it breaks down a little bit, so it makes it a little easier to foam. But yeah, definitely, we have customers run 100 percent regrind, and it foams beautifully,” he said.

Whether the goal is to save resin for environmental or financial reasons, or simply stretch it, filling and foaming are two ways to make resin go a little further.

“This is what I tell people: If the foam can expand in that polymer, we can foam it, and if we can’t foam it, we can fill it,” Bishop said.

Karen Hanna, senior staff reporter

Contact:

iD Additives, La Grange, lll., 708-588-0081, www.idadditives.com

Karen Hanna | Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.