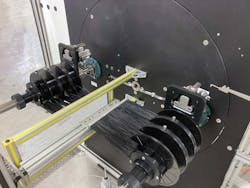

ATC Series ATC Series coilers from Conair are dual-spindle units that provide tensionless, high-speed winding of flexible tubing measuring from 1mm to 12.7mm in diameter on coils up to 2 feet in diameter. The coiler automatically cuts the tubing and shifts over to winding a new coil when a coil is completed, eliminating the need for operator involvement or disruption of the process. Its floor-mounted ultrasonic loop sensor monitors the incoming product, automatically adjusting the coil speed and traverse motion to wind the tubing smoothly, without the friction or tension that can damage delicate extruded tubes. Part of a complete line of downstream extrusion equipment from Conair, the coiler features a servo-drive for a high degree of repeatability in speed and positioning.

What’s new? The ability to wind multiple small spools. The spools are loaded onto the coiler’s twin shafts. Once tube extrusion begins, the coiler is programmed to wind one spool at a time until all the spools on one shaft are full. Then the coiler moves the shaft with empty spools into position. The automatic coil-isolation feature actuates safety gates to prevent operator access during shaft transition. After the transition is complete, operators can safely remove full coils and load new spools in preparation for the next cycle. Conair introduced the new feature this spring and is targeting medical tubing extruders and other manufacturers that need to produce small-quantity spools.

Benefits Simplicity. The new feature eliminates the need to cut and rewind tubing from larger coils to fulfill smaller orders.

Conair Group, Cranberry Township, Pa., 724-584-5500, www.conairgroup.com

Request More Information