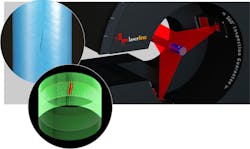

FlawSense LaserLinc’s measurement system addresses some of the flaws of traditional measurement techniques used to detect defects in wire, cable, pipe and tube product. Some traditional techniques can’t measure the product’s full contour; others offer only limited measurement points per sensor, or are prone to false positives triggered by text or labels. In contrast, FlawSense uses high-speed laser line triangulation to provide 360-degree inline or offline inspection, regardless of product orientation in the measurement field. It’s ideal for measuring high-specification, high-value products including medical devices like catheters and medical tubes, complex armored cable, and high-pressure hoses for the automobile and aerospace industries.

What’s new? FlawSense.

Benefits Precise, reliable measurement, improved product quality and lower scrap and rework levels. FlawSense’s resolution is 10 times better than camera-based systems. It reliably detects lumps, gels, pits, slits and other surface defects as small as 5 microns. It digitizes thousands of measurement points around the product’s contour, then produces a 3D point cloud image that can be used for further analysis.

LaserLinc, Fairborn, Ohio, 937-318-2440, www.laserlinc.com

Vital Statistics

Model 3-029 | Model 3-069 | |

Minimum outer diameter | 1mm | 3mm |

Maximum outer diameter | 29mm | 69mm |

Minimum detectable defect height | 5 microns | 25 microns |

David Tillett | Associate Editor

Associate Editor David Tillett writes and edits for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He covers new products, industry news, patents and consumer and business equipment. He has more than 20 years of experience in daily newspaper, online and magazine journalism.